What are the Functions of Twin Ferrule Tube Fittings?

Compression fittings are used to quickly and easily make leak-free tube connections. Twin ferrule compression fittings are available in metric and fractional tube sizes and include:

- An exterior nut.

- Two soft alloy or non-ferrous metal ferrules can be deformed.

- A tube-fitting body.

The ferrules flex when the fitting nut is tightened on the tube, creating a tight seal.

Compression Tube fittings of twin ferrules Fittings are low-maintenance and may be removed and reassembled without losing their leak-tightness. Twin Ferrule Tube Fittings are also vibration fatigue resistant and can be used with harsh chemicals.

What is Twin Ferrule Fittings?

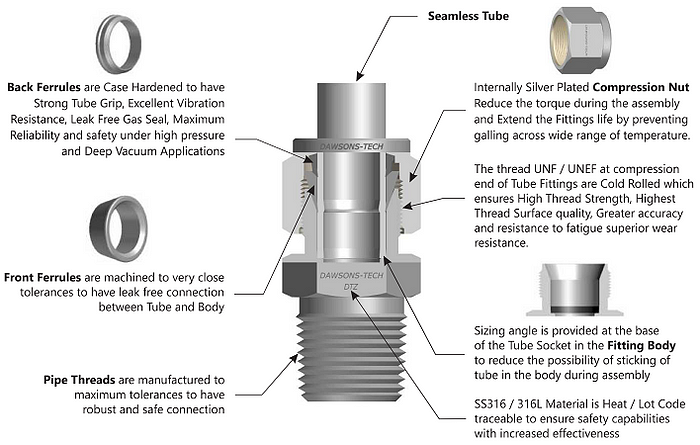

Body, nut, front, and back ferrules are the four precision elements that make up a twin ferrule tube fitting. When tubing is added, it becomes a five-component system while sealing and tube the two ferrules separate gripping activities. The front ferrule forms a seal against the fitting body and the outside diameter of the tubing. The back ferrule compresses the front ferrule as the nut is rotated, developing an efficient tube grip.

Twin ferrule tube fittings are simple to install, and Welding or threaded ends are not required for the connections. It shifts to cost-cutting, resulting in less dependence on people. They can be reused multiple times while maintaining a cheap material cost. The following are some of the advantages of employing a double ferrule fitting:

- Provide optimum flexibility and strength

- High corrosion resistance and chemical resistance

- Keep severe temperatures at bay.

- In a harsh or high-stress nuclear environment, high-pressure resistance is essential.

Functions of Twin Ferrule Tube Fittings:

When the nut is screwed onto the body and tightened against the tapering section of the body, the edge of the nut curls inward, compressing the tube tightly.

The back ferrule, which is positioned between the nut and the body, roll up while the front ferrule rolls and bites into the tube, providing a leak-proof seal as well as a connection between the fitting and the tube.

All assembly and reassembly motion is transmitted axially through the tube, resulting in leak-proof sealing. Due to this, the tube does not move radially during installation, and it is not weakened while the mechanical integrity of the system is preserved. The machining, surface smoothness, and hardness of each part of the twin ferrule tube fittings are all held to tight tolerances.

How do you utilize a compression fitting with twin ferrules?

When properly constructed, twin ferrule fittings perform admirably; leaks can still happen due to faulty tube fitting or loose connection. Fittings assembly is simple to understand and begin.

First, cut your tube to the appropriate length, ensuring the ends are square and free of burrs.

The tube must then be firmly pushed inside the twin ferrule fitting until it comes to a stop inside.

Before tightening the nut, indicate the beginning point at the 6 o’clock position.

After that, simply turn the nut 1–1/4 times to ensure the tube is securely fastened. At the 9 o’clock position, the starting point is established.

The most incredible thing about twin ferrule fittings is long-lasting and reused. For a different tube, the pieces can be dismantled and rebuilt. Due to severe fluid pressures, a twin ferrule tube fitting ensures that the parts never lose shape or strength.

DAWSONS-TECH ensures the dependability of our compression fittings by using two ferrules instead of one. This technology is designed for strength and ductility, making it ideal for oil and gas, chemicals and petrochemicals, alternative fuels, and semiconductors.